Part II Emission Possible - Building an affordable path to net zero

Industry Case Studies for the Decarbonization of Schools

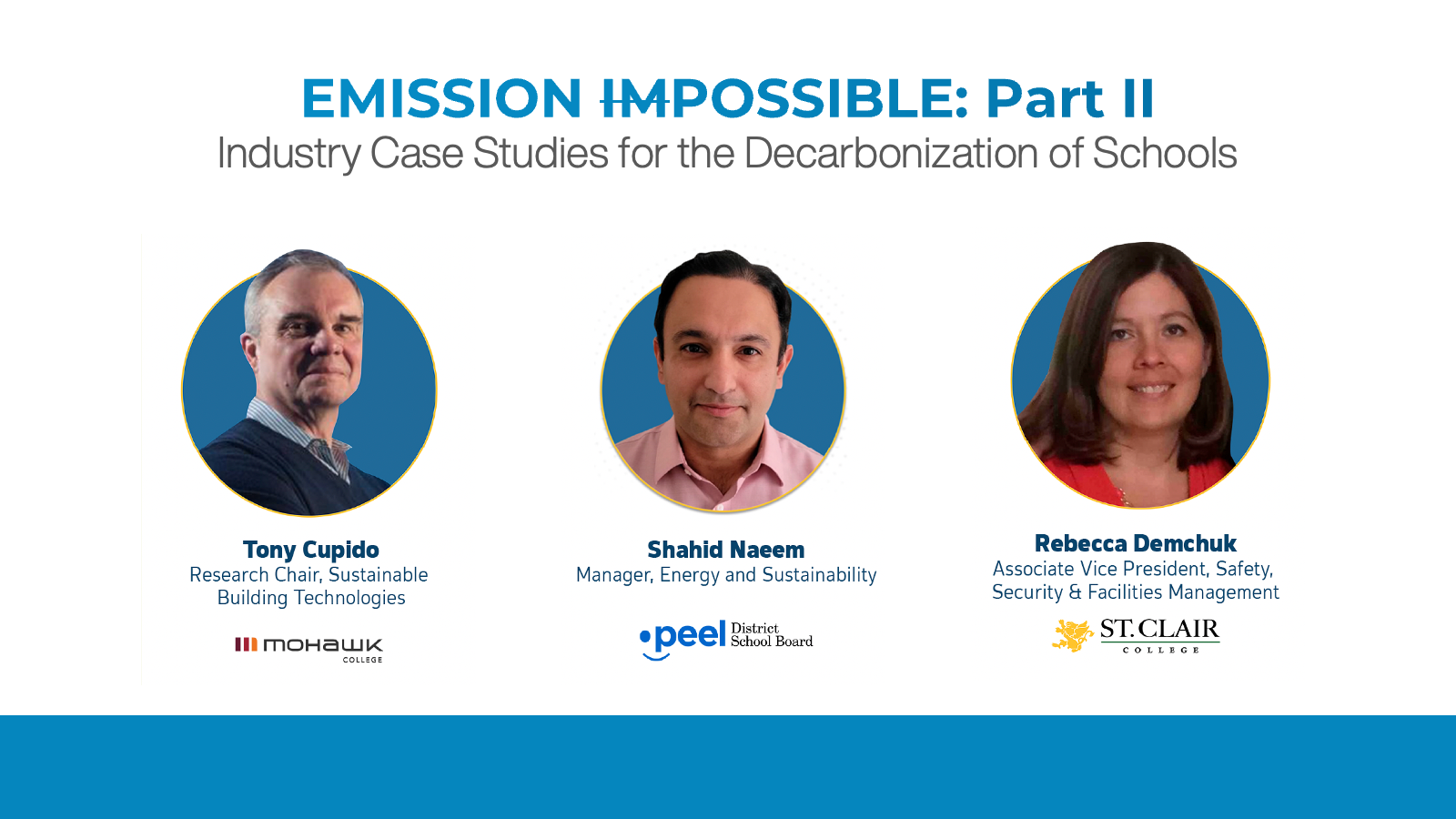

The panel discussion was moderated by Tony Cupido, to show how both of these institutions are successfully reducing energy waste and greenhouse gas emissions through a variety of active decarbonization initiatives.

Tony Cupido, the Research Chair, Sustainable Building Technologies has served as Superintendent of Facilities for both Hamilton Wentworth DSB and Hamilton Catholic DSB, as well as Associate Vice President of Facilities at McMaster University and Chief Building and Facilities Officer at Mohawk College. He has been a strong advocate for green building initiatives, shaping policies and educational programs. He played a pivotal role in the development and early operation of Canada's largest zero-carbon institutional building—The Joyce Centre for Partnership and Innovation at Mohawk College.

Shahid Naeem, Energy & Sustainability Manager at the PEEL District School Board, and Rebecca Demchuk, the Associate Vice President of Safety, Security & Facilities Management at St. Clair College. Shahid and Rebecca have demonstrated leadership in energy conservation and reducing greenhouse gas emissions through practical and measurable initiatives.

In Part 1 of Emission Impossible - Building an affordable path to net zero

Josh Lewis, VP Engineering, Nerva Energy, emphasized the critical role of energy conservation and mechanical optimization in our journey towards 2030 and 2050. The main takeaways were straightforward: Conserve first, then optimize, and finally, convert.

Please tell us about PEEL’s decarbonization goals for the mid and long-term future? Are there any benchmarks you have committed to?

The Peel District School Board, is committed to aligning our decarbonization goals with the priorities set forth by the Ministry of Education. As a publicly funded institution, it's essential that we operate in accordance with their direction.

To date, we've made significant progress in our sustainability efforts. We've developed and implemented two comprehensive Energy Conservation and Demand Management Plans, which have been instrumental in guiding our actions. These plans have already led to a 39% reduction in GHG emissions, a reduction of just over 200,000 metric tonnes of CO2e.

Looking ahead, we remain dedicated to improving our environmental performance. However, we must do so while staying mindful of the financial constraints we face. Therefore, our future decarbonization goals will be closely tied to the Ministry of Education's priorities. We aim to continue making responsible and sustainable choices as we move forward.

How is St. Clair approaching this decarbonization journey?

We do have several challenges as we move forward on our decarbonization journey. Currently, our strategy is to make changes through our deferred maintenance program. As equipment is scheduled to be replaced, instead of replacing like for like, we look at options to reduce green house gas by considering equipment such as heat pumps, electric boilers, and hybrid HVAC units. We will have an engineering study completed with respect to the options available, looking at both the actual demand (not assuming the existing equipment capacity is still correct), determining the new demand created to electrify and then reviewing costs, both capital and operational. We then make a business case, if feasible, to move forward with the low GHG option. In addition, we’re always look to improve efficiency when replacing equipment, upgrading motors, VFD’s and controls so that we can optimize the equipment functionality. Lastly, we have engaged duct sealing technology on some of our main HVAC systems. This allows us to review and clean the existing ductwork, address any gaps and seal it against gas leakage.

The goal to 2023 is based on the above strategy based on optimization and right sizing. Beyond that, we are evaluating options for a combination of solar-thermal, PV, geothermal and electrification. We are also having conversations with our electricity providers about our future demands so that both the College and the LDC understand what the costs and needs will be to allow us to eventually run the main plants without natural gas.

During Part 1 of this webinar, we learned about the importance of energy conservation. Can you tell us what that means to you and perhaps any particular projects and results?

In addition to equipment upgrades (VFD’s, motors, controls, BAS), Rebecca touched on the importance of understanding ventilation performance. She expressed that the environment we provide for our students and staff is a priority along with the energy cost and the emissions generated by it. An older campus has significant issues with airflow, balancing, and duct leakage. We decided to conduct a comprehensive audit to quantify the actual leakage rates for each system and in every room. This helped to paint the picture on the benefits of eliminating that leakage. Any air you lose means wasted energy and excess emissions, so that became a key focus for us. We’ve completed 3projects to date and have achieved an energy cost reduction of $236,247 and lowered our carbon footprint by 385 tonnes.

Project Performance Summary

Project Cost: $683,000

Incentive: $76,551

Project Cost minus Incentives: $606,449

Annual Energy Savings/Year: $236,247

SPP (Years): 2.6

Cumulative Savings

5-Year $1,254,267 (Cashflow: $647,818)

10-Year $2,708,307 (Cashflow: $2,101,858)

15-Year $4,393,938 (Cashflow: $3,787,489)

We conducted a pilot project at two schools, one a secondary school and the other a K-8 school, to test the efficacy of a new technology. We utilized a similar methodology to St. Clair College, which involved a detailed modeling of the equipment and settings, to quantify the performance of the technology before and after implementation. Additionally, we cross-verified the estimated energy savings against real-time interval utility meters. Our findings indicate that the technology is delivering approximately 15% energy savings.

AHU replacement and annual renewal as well as lower future electrification costs by gleaning out the waste first – smaller GEO system will be the result.

Through our duct sealing efforts we’ve uncovered opportunities to right-sizing and optimize our mechanical systems. Ensuring that it aligns precisely with our needs, we've not only reduced energy consumption but also reduced capital and operating costs for both new construction and renewal facilities. This financial savings are crucial, especially when considering future energy projects.

Secondly, our increased efficiency in operations has translated to improved comfort for our students and staff. Comfortable learning and working environments directly impact student performance and employee satisfaction. So, we now place a higher emphasis on projects that enhance occupant comfort, which contributes to our overall evaluation criteria.

Thirdly, by reducing greenhouse gas emissions, we are aligning with broader sustainability goals and commitments. This aligns us with various government regulations and initiatives that encourage greener practices. So, when evaluating new projects, we now look for opportunities to further reduce our carbon footprint.

In summary, our journey in duct sealing equipment, optimizing systems, and improving efficiency has expanded our evaluation criteria. We now prioritize projects that not only save energy but also reduce costs, enhance occupant comfort, and align with our sustainability goals. This broader perspective ensures that our energy projects contribute positively to our schools' overall performance and the well-being of our students and staff.

While we've made significant strides in improving ventilation, we're also actively pursuing other energy conservation measures to further reduce our environmental footprint and operational costs.

One of our key initiatives is LED lighting retrofits. We've been steadily implementing these retrofits, targeting 6 to 7 facilities each year. This not only enhances energy efficiency but also improves lighting quality, creating better learning environments for our students and staff.

Another important area we're focusing on is variable frequency drive retrofits for our heating and cooling plants. By optimizing the operation of these systems, we can achieve substantial energy savings while maintaining comfortable indoor conditions.

We're also actively engaged in pay-for-performance programs with organizations like IESO and Enbridge. These programs provide us with incentives to implement energy-efficient measures, further enhancing our commitment to sustainability.

Additionally, we recently signed a memorandum of understanding just before Christmas for the installation of electric vehicle charging stations at our secondary schools. This aligns with our broader sustainability goals and promotes the adoption of electric vehicles within our community.

Finally, we continue to prioritize commissioning and recommissioning of facilities. This process is integrated into every major facility renewal project we undertake. It ensures that our buildings are not only energy-efficient from day one but also maintain optimal performance throughout their lifecycle.

Our efforts extend beyond ventilation, encompassing LED lighting retrofits, variable frequency drive upgrades, participation in incentive programs, electric vehicle charging infrastructure, and a strong commitment to commissioning and recommissioning. These measures collectively contribute to our mission of reducing energy consumption and fostering sustainability within our school district.

HVAC is a significant portion of our energy consumption. Improving ventilation is also a key priority. We have worked to identify areas that run continuously and are installing CO2 monitors in key locations. We’ve also upgraded our BAS and are working on scheduling according to usage. Making modifications to our event spaces, large classrooms, ballrooms, and gyms, to control ventilation by need.

All campuses have been upgraded to LED lighting, both interior and exterior, with occupancy control, photo cells, etc.

In addition, we have completed building sealing projects where studies have shown significant leakage through windows, caulking, and building exterior.

I should note that we have engaged an Energy Manager to help us through this process. We work with Jeff and his company to work through these various projects, review the M&V, create the energy portfolio across all sites, apply for incentives to help further our program and identify year to year projects.

Mechanical optimization and ventilation improvements are currently our key priorities as they affect the comfort level of our customers (students) and our staff, in addition to affecting the overall energy performance of the campus. Through both operational and capital improvements, and working with our energy, air balancing and controls partners, we are reviewing system by system opportunities for optimization. Utilizing several sources of information from equipment downtime, equipment age, energy consumption, complaints, etc., we prioritize systems to address on an annual basis. Optimization may include schedule changes within the BAS, replacing old motors with those compatible with VFD’s and installing VFD’s, upgrading the controls associated with the equipment from pneumatic to electronic, duct sealing and/or air balancing.

Where we need to keep gas fired equipment for now, we are optimizing with the most efficient equipment available, and using Energy Recovery Ventilators wherever possible.

At Peel District School Board, we've indeed taken a holistic approach to our facilities, recognizing that it's not just about energy conservation but also about optimizing the mechanical systems that support our schools.

Our focus has been on developing a people-centric approach that combines capital improvements with operational efficiencies. We use interval energy data to identify opportunities for improvement, and we align these opportunities not only with the needs of our students but also with our maintenance and custodial operations. This approach ensures that our facilities are not just energy-efficient but also conducive to a productive learning environment.

We continuously track and optimize our facilities through our building automation systems. Additionally, we've instituted a policy of recommissioning our facilities. To date, we've completed close to 6 million square feet of recommissioning. This process allows us to ensure that renewal and new construction projects deliver results from day one, and it also provides us with an ongoing list of cost-effective capital measures that we can implement to further enhance the performance of our facilities.

So, our strategies include a people-centric approach, leveraging interval energy data, continuous tracking and optimization through building automation, and a robust recommissioning policy. These strategies not only contribute to energy conservation but also to the overall effectiveness of our facilities in supporting student learning and well-being.

How should our webinar attendees approach measuring and tracking energy performance?

How can you quantify outcomes and validate any financial benefits associated with each measure?

Measuring and Tracking Energy Performance: It's important to recognize that every organization is unique, and the approach to measuring and tracking energy performance should align with your specific needs and resources. For larger organizations like ours, where the operating expenses justify it, we've found that continuous facility-level Measurement & Verification (M&V) is invaluable. This involves real-time monitoring of our facilities' energy performance. We've enrolled our largest 30 facilities in pay-for-performance energy incentive programs, and these have proven to be very useful in tracking performance. They not only provide incentives for improved performance but also offer third-party verification, which adds an extra layer of credibility.

Quantifying Outcomes and Validating Benefits: To quantify outcomes and validate financial benefits, we use a comprehensive approach. We normalize energy consumption data for factors such as facility area, weather conditions, construction variations, or any other influencing factors. Normalization allows us to compare the performance of different facilities on an equal footing and assess the true impact of our energy conservation measures. We also pay close attention to the reduction in energy expenses, but we don't stop there. We consider other potential benefits, such as reduced maintenance and custodial operations costs. By taking a holistic view, we ensure that we capture all the financial advantages associated with each energy conservation project.

Evaluating Energy Conservation Projects: When evaluating energy conservation projects, we look for tangible financial outcomes. This typically includes a reduction in energy expenses, which is a direct result of our energy-efficient measures. Additionally, we assess any incentives or rebates gained through participation in energy programs. But our perspective extends beyond just financial metrics. We consider the overall impact on our facilities' performance, energy resilience, and, most importantly, how these improvements contribute to a healthier and more conducive learning environment for our students.

Our approach centers on continuous measurement and verification, normalization of data for accurate assessment, and a holistic evaluation that goes beyond financial gains. We believe that this multifaceted approach ensures that we not only achieve energy savings but also enhance the overall quality and sustainability of our facilities.

We have meters in various locations on campus, however, we certainly need more. We have pulled the meters onto our system so that we can monitor high use areas, from both an electrical and natural gas usage perspective. Monitoring and tracking energy performance has enabled us to identify the highest use areas and investigate the reasons behind that. For example, the most recent exercise showed that our downtown campus event centre, and our Sportplex have a significant impact on our energy profile. We have targeted both buildings for the IESO Existing Building Commissioning Program (EBCx). Both applications have been approved and are underway. The results of the M&V with our duct sealing projects showed the significant benefit to the program and allowed us to receive additional funding to proceed with sealing additional systems.

When evaluating projects, we always look at overall cost from both an operational and capital standpoint. The traditional ROI does not always work in these project reviews as the costs for electricity, for example, may actually increase. We review the change to both the electricity and natural gas consumption estimated to result from implementing the project, and their associated cost impacts. This helps us to determine the highest value projects to proceed with. Some projects have high cost with minimal impact on overall energy portfolio. These projects would not be prioritized.

As we look ahead to meet our 2030 and 2050 GHG commitments, I see these milestones as not just targets but as opportunities for growth and development in our profession.

Meeting these commitments will require us to capture inefficiencies through the adoption of new technologies and innovative approaches to how we manage our facilities. It's about pushing the boundaries of what's possible and finding creative solutions to reduce our environmental footprint while enhancing the quality of our learning environments.

However, I believe that achieving these goals goes beyond the technical aspects. It requires strong leadership to drive these initiatives from a strategic perspective. It means including these commitments and their associated performance metrics at the highest levels, such as the Board of Trustees. It's about creating a culture of sustainability and responsibility that permeates every aspect of our organization.

In essence, these commitments are not just about reducing emissions; they're about transforming our approach to facilities management and education. They're about creating a legacy of sustainability and innovation that benefits not only the current generation of students but also those who will follow in the years to come.

So, to sum it up, I see our journey evolving into one of continuous improvement, driven by innovation and leadership, as we work together to achieve our 2030 and 2050 GHG commitments.

This is the greatest challenge as we sit here. I truly believe that we cannot all do this in isolation, and it will take community-based approaches to achieve the 2050 goals set out. It will also take significant funding and top-level commitment.

We are using existing equipment optimization, “right sizing”, BAS upgrades and equipment replacements (when scheduled) to help meet our shorter-term goals. Longer term, we are evaluating which technologies will best suit our needs at each campus/building that we have. We have completed several studies on geothermal, solar and electrification, and will continue to do so. We also need to closely collaborate with our electricity providers, to build a plan to meet future goals. We have 26 buildings in our portfolio so looking at it building by building is essential.